Properties of Polyamide PA66

2020-11-16 17:02

92

Polyamides are among the most important thermoplastic synthetic materials. Thermoplastics can be reshaped by heating as often as required without undergoing chemical decomposition or other negative changes. This makes polyamide ideal for processing via injection moulding into high quality products. About 90 % of cable ties and fixings from HellermannTyton are made from this material. Polyamide is also known under the brand name of Nylon®, which was introduced by the Dupont company. The inner structure of polyamide displays a partial order of polymer chains, i.e. polyamides are partially crystalline. Due to the tighter packing of the individual molecular chains polyamide only has limited transparency to light. The plastic is therefore described as translucent.

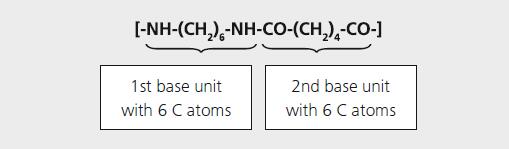

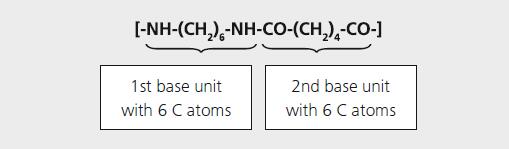

The molecular chains of PA66 are made from two base units:

Each base unit contains 6 carbon atoms (C). Hence the name PA66. The polyamide PA66 has many properties which are highly advantageous for HellermannTyton cable ties and fixings, such as:

• High strength, rigidity and hardness

• High dimensional stability, even under the effect of heat

• High abrasion resistance

Having a wide range of polyamides and additives allows for an optimum adaptation of the properties of the finished product to suit the respective requirements.

The following PA66 variants are used for HellermannTyton products:

• Polyamide 6.6 standard (PA66) for temperature conditions of

up to +85 °C

• Polyamide 6.6 Heat Stabilised (PA66HS) for temperature conditions of

up to +105 °C

• Polyamide 6.6 UV Stabilised (PA66W) for exterior use

• Polyamide 6.6 Heat Stabilised and UV Stabilised (PA66HSW) for

exterior use up to +105 °C

• Polyamide 6.6 Impact Resistant (PA66HIR) for high elasticity requirements

• Polyamide 6.6 Impact Resistant and Heat Stabilised (PA66HIRHS) for

high elasticity requirements and temperatures up to +105 °C

• Polyamide 6.6 V0 for high standards of fire protection

Water content in polyamide Polyamide is a hygroscopic material - this means that it absorbs and releases water. The mechanical properties are significantly affected by the water content – especially flexibility and minimum tensile strength. In a standard atmosphere of 23 °C and 50 % relative humidity, the degree of water saturation of polyamide is around 2.5 %. For optimal processing of cable ties it is therefore important that the polyamide has a water content of approximately 2.5 % in a state of equilibrium. The quality and functionality of the products are thus affected by the water content, therefore the correct storage of our products is crucial. Please read our separate instructions on storage. Since humidity is so critical to the quality of the tie, the question arises: What happens if the tie is installed and the water content in the tie alters? The water content determines the flexibility and strength of a tie. At a water content of approximately 2.5 % the tie has the ideal flexibility for installation. When the strap is being threaded through the head of the tie, the pawl must be flexible enough to “see-saw” over the serration of the strap without breaking. On the other hand, there must also be adequate material rigidity for the serrations of the pawl to engage with the serrations of the strap during the tying process so that a 'positive locking' action is achieved. After achieving the positive locking action the tie is in a static condition. Changes in the mechanical properties of the tie as a function of water content are insignificant during this status.

- Previous:Chemical resistance of various plastics

- Next:No more