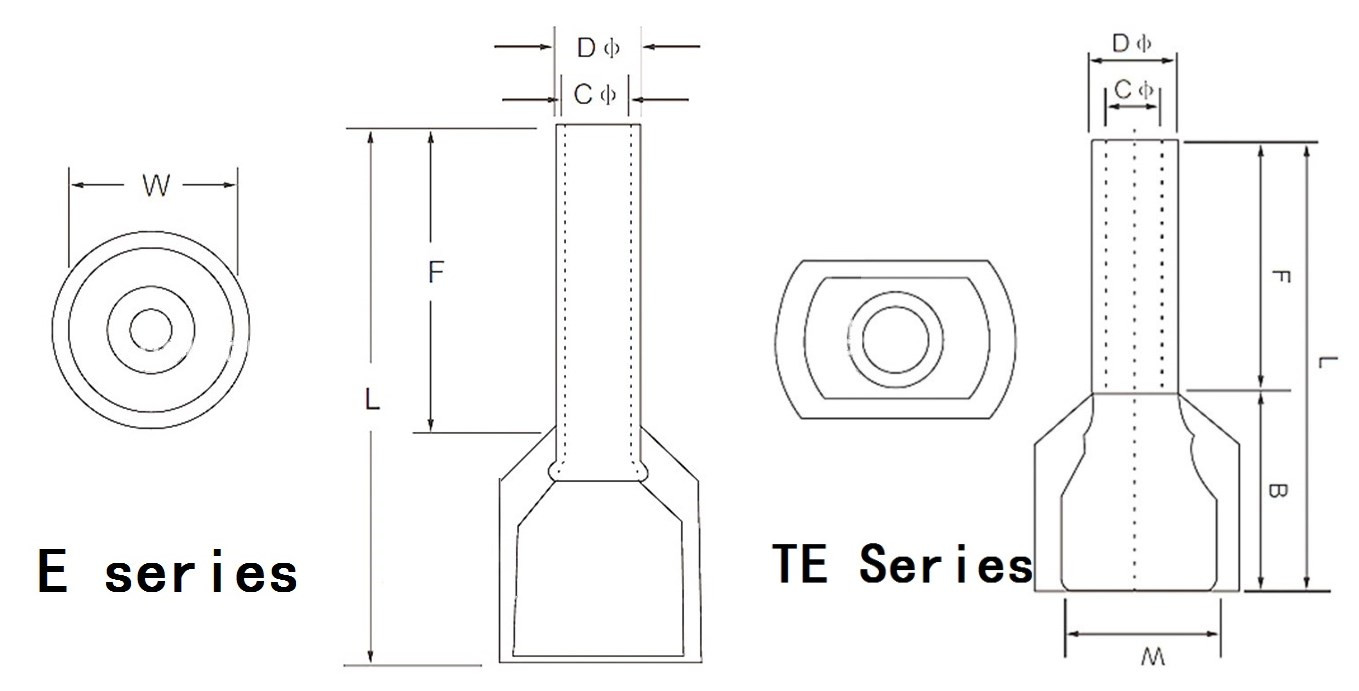

Insulated Ferrules

Tin Plated Copper

Maximum Operating Temperature: 221 °F (105 °C)

Tin Melting Point: 449.47 °F (231.93 °C)

Copper Melting Point: 1984.32 °F (1084.62 °C)

Maximum Electrical Rating: 105°C (221°F) - 600 Volts

Insulation Maximum Operating

Temperature: 221°F (105 °C)

Minimum Operating Temperature: -94°F (-70 °C)

Melting Point: 420 °F (216 °C)

Tensile Strength: 5,800 psi

Hardness: R92

Specific Gravity: 1.13

Insulated: Polypropylene insulation housing conforms to DIN color requirements, meets DIN standards for single wire containment, funnel entry for faster insertion and lower installed cost, designed with a seamless barrel to contain loose wire strands for superior terminations, eases insertion of wire into terminal block, suitable for limited space panel applications, multiple pin lengths available for a variety of terminal blocks.

- Previous:No more

- Next: Ring Terminals